By using state-of-the-art production technology, our production line is constantly evolving.

We analyze the cause and mechanism of any and all possible failures during the production process and adopt methods such as FMEA (Failure Mode and Effect Analysis) to improve results, thus reducing any impact on our customers.

We have conducted a substantial review of the existing facilities, cut down the number of processes and redesigned the total length of the production lines to make it shorter.

We will rebuild the production lines with better efficiency.

In pursuit of expanding automation, we use all-purpose robots in accordance with each process’s specific function.

We use industry standard products/parts for smooth operation and remodeling

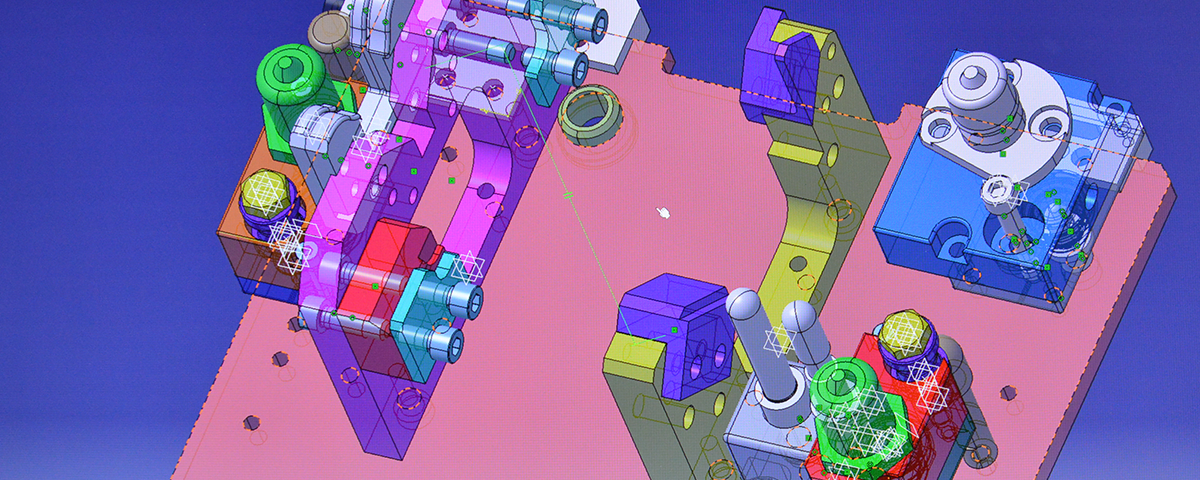

We promote digitization by adopting technology such as 3D-CAD, attempting always to avoid any trouble while at the same time sharing past mistakes, thus reducing the number of manufacturing errors, even to zero in many cases.